Products

A wide range of rotors and the size of the hopper of series HGX enables adaptation to almost every process in recycling. HGX series is used as granulators for processing large elements one step or as a second stage after the initial reduction. HGX mills can be adapted to the initial washing of raw material as well as for grinding materials highly abrasive and contaminated by abrasive discs.

Heavy steel welded construction is designed to work in harsh conditions. HGX series mills can be equipped with different versions of rotors with V-cut, Cascading, straight, Diagonal which allows for the best matching machines for manufacturing needs. Location of the bearings on the outside of the machine protects them from contamination. Reinforced bearing sleeve ensure continuity of work and changing.

Standard

- reinforced bearing

- different versions of rotors

- hydraulic open

Option

- flywheel

- belt feeder

- abrasive plates

Specification

| HGX600 | HGX700 | HGX800 | HGX1000 | HGX1200 | |

| HOPPER (mm) | 620 x 600 | 720 x 700 | 820 x 800 | 1020 x 850 | 1220 x 900 |

| ROTOR DIAMETER (mm) | 600 | 700 | 800 | 1000 | 1200 |

| ROTOR WIDTH (mm) | 550 | 550 | 590 | 600 | 600 |

| POWER (kW) | 37 / 45 | 45 / 55 | 55 / 75 | 75 / 100 | 110 / 135 |

| NUMBER OF ROTARY KNIVES | 4 / 5 | 4 / 5 | 5 / 6 | 5 / 6 | 5 / 7 |

| NUMBER OF STATOR KNIVES | 2 | 2 | 2 | 2 | 2 |

| SCREEN SIZE | 6 / 15 | 6 / 15 | 8 / 20 | 8 / 20 | 8 / 20 |

| WEIGHT (kg) | 2200 | 2500 | 3000 | 4000 | 4600 |

| CAPACITY (kg/h) | 600 / 1000 | 800 / 1200 | 1200 / 1800 | 1600 / 2500 | 2500 / 3500 |

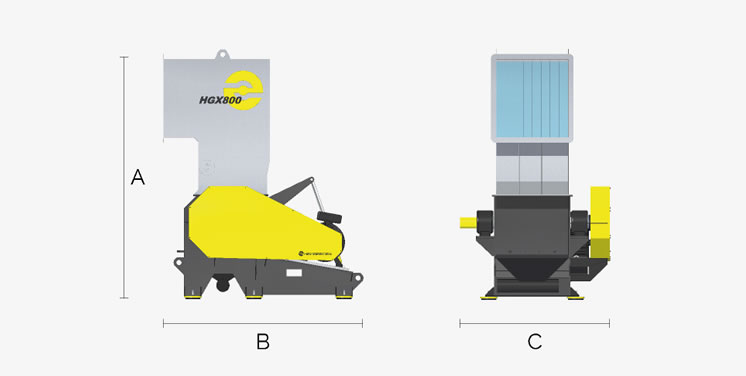

| A (mm) | 2200 | 2450 | 2600 | 2700 | 2850 |

| B (mm) | 2000 | 2000 | 2100 | 2200 | 2300 |

| C (mm) | 1500 | 1600 | 1700 | 1900 | 2100 |